Biological Wastewater Treatment Solutions

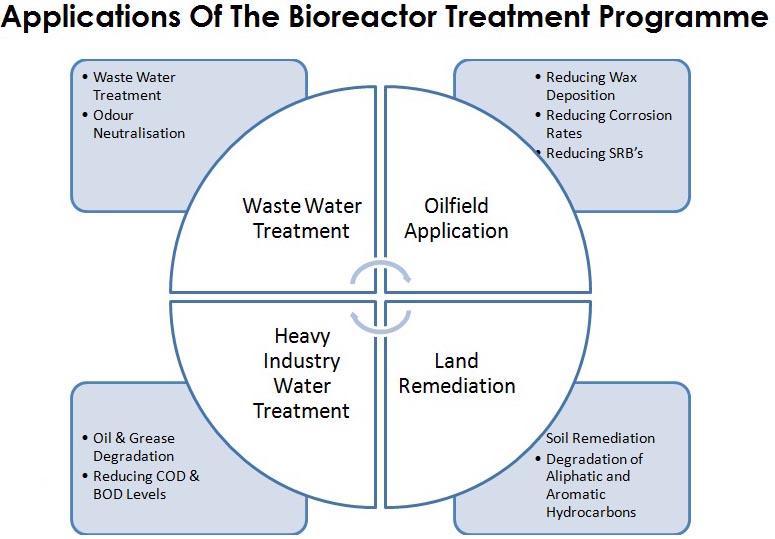

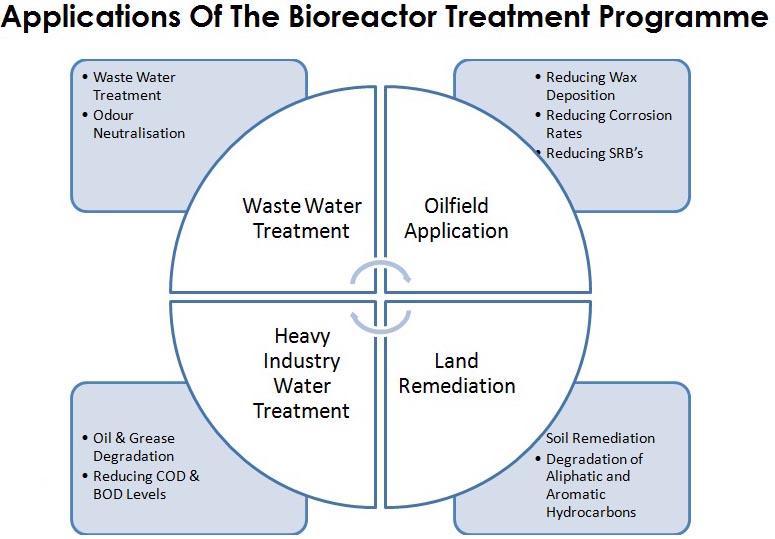

The Chemiphase Bioreactor is a bacteria growing module which provides all of the necessary growing conditions for substantially enhanced bacterial growth. By maximising all of the conditions for bacterial growth we can treat waste streams with a wide range of biological treatments for various problems such as fat & grease, hydrogen sulphide. Using bacteria streams to treat these potential issues we are able to offer much more cost efficient treatment programmes that are just as effective as common chemical treatments yet don't have as many potential environmental concerns as their chemical rivals. Because of the nature of bacteria they will continually generate fresh bacteria allowing them to treat a much larger volume of material, it is because of this re-generation that makes the bioreactor system much more cost efficient.

Chemiphase Bioreactor for biological wastewater treatment

The bioreactor is a dosing station that is situated on site at a point that will allow maximum coverage and efficiency. After an initial dosing period, the bioreactor will intermittently dose a measured amount of Biosure product directly to the waste water, ensuring a sustained bacterial treatment. This dosing is frequently monitored and adjusted to not only optimize the bacterial impact, but in order to achieve the highest level of cost efficiency.

Chemiphase Bioreactor Product Range

The Biosure range is a specially formulated, select microbial product designed to control and suppress the problems associated with municipal, oilfield and industrial biological waste water treatments. The unique formulations are carefully engineered to tackle the most common of issues

Key Benefits

- Thorough bacterial coverage eliminates waste water treatment problems

- Rapidly established BOD and COD removal

- Odour neutralisation

- Biological wastewater treatment

- Continual dosing

- Fast, noticeable results

- Technical advice and bioreactor optimization

- Testing and analysis

- Cost effective

- On site support

Chemiphase Bacterial Options

Below is a brief breakdown of the Biosure product range and a description of the issues they have been formulated to address, with the typical application areas.

The Biosure biological wastewater treatment products have been specifically engineered and refined to meet the needs of the waste water treatment industry. Through our extensive experience and working partnerships with numerous waste water treatment plants, our in house and onsite testing and constant product development we are confident the Biosure range offers the ultimate in microbial treatment plans.

|

PRODUCT

|

DESCRIPTION

|

APPLICATION

|

PDF

|

|

CP- 1050

|

Control Of Filamentous Bulking

|

All Industries

|

|

|

CP- 1055

|

Biomass Start Up

|

Municipal

|

|

|

CP- 1060

|

Degradation of Fats and Greases of Animal Origin

|

Dairy and Food Processing

|

|

|

CP- 1065

|

Degradation of Fats and Greases of Vegetable Origin

|

Vegetable Oil Processing

|

|

|

CP- 1070

|

Degradation of High Strength Proteinaceous Wastes

|

Meat Processing/ Faculative Lagoons

|

|

|

CP- 1075

|

Degradation of Detergent

|

Detergents

|

|

|

CP- 1080

|

Degradation of Starches and Cellulosic Materials

|

Pulp and Paper/ vegetable Processing

|

|

|

CP- 1085

|

Degradation of Solvents, Amines and Phenolics

|

Chemical Industry

|

|

|

CP- 1090

|

Degradation of Aliphatic and Aromatic Hydrocarbons

|

Soil Remediation

|

|

|

CP- 1095

|

Degradation of Petroleum Hydrocarbons

|

Oil Refineries

|

|

|

CP- 1100

|

Oxidation of H2S

|

All Industries

|

|

|

CP- 1115

|

Degradation of Halogenated Aromatics, Removal of AOX

|

Chemical/Pharmaceutical/Pulp and Paper

|

|

|

CP- 1120

|

Nitrification- Oxidation of Ammonia

|

All Industries

|

|

|

CP- 1130

|

Nitrification- Oxidation of Nitrate

|

All Industries

|

|

|

Algae Clear Powder

|

Degradation of Organic Material

|

Lakes and Ponds

|

|

|

Algae Clear F Powder

|

Degradation of Organic Material

|

Lakes and Ponds

|

|

|

Grease Eater Powder

|

Degradation of Fat and Grease

|

Food Industries

|

|

How the Biosure Products work

The Biosure products are bacterial cultures which use their free enzymes to effectively digest organic waste and odours. Bacteria are unicellular micro-organisms that are present throughout the environment. All bacteria must eat to stay alive. The bacteria produce enzymes that break down organic waste into a liquid form that can be easily absorbed by the bacteria. The bacteria convert the liquid into energy (for use within the bacteria) CO2 and H2O. The CO2 and H2O are released as harmless by products into the environment.

The energy is used by the bacteria for reproduction. Biological wastewater treatment bacteria reproduce by subdividing, forming two bacteria. Time frames of this sub division vary but will occur approximately every twenty minutes. With this in mind it is easy to see how an introduced bacterial culture can quickly begin to work at degrading organic matter. Each product in the Biosure range contain a carefully selected blend of bacterial strains. These bacteria have been selected, adapted , grown in pure culture, harvested and preserved before being blended into the final formulation. In addition to the bacteria the products also contain amylases, cellulases and lipases as free enzymes, which are important in the initial growth phase of the bacteria. The bacterial make up of each of the Biosure product varies in accordance to its primary function (i.e. what its primary organic feed stock will be). This is how we are able to offer a variety of bacterial treatment packages to combat varying waste issues.

The Chemiphase Biosure Biological Wastewater Treatment

Chemiphase have moved from the concept of treating individual areas to the present mode of operation, namely the use of bioreactors. The bioreactor feeds the incoming effluent water with an effective inoculation of the Biosure bacterial product. The Chemiphase Biosure Bioreactor is installed at a convenient point that ensures as full a coverage as is possible. From this point the bioreactor continually doses the biological wastewater treatment system to encourage the bacterial coverage.

The bacteria gains a foot hold within the ecosystem quickly, the continual dosing is necessary due to the flowing nature of the waste water system .

The Chemiphase Biosure Bioreactor consists of the following;

- Supply and maintenance of the Chemiphase Biosure Bioreactor and all ancillary equipment.

- Supply of all Chemiphase Biosure Bioreactor biological cultures.

- Supply of nutrient package.

- Semi-monthly Chemiphase Biosure Bioreactor service to check the health of the biomass and carry out other essential checks. (See parameters set out below).

- Provide an emergency call out system to ensure the Chemiphase Biosure Bioreactor Programme is not interrupted unduly.

- Quote installation costs and then a monthly price for each site. These prices will include the purchase of the equipment, the supply and maintenance of the bio-culture and the supply of nutrients. The servicing and maintenance of the equipment will be free of charge whilst the bio-culture and nutrients are purchased.

The Chemiphase Biosure Bioreactor Service Programme will include the following “health checks”:

- pH

- Dissolved oxygen

- NH4 ions

- Biological wastewater treatment

- Phosphate ions

- Glucose / sugar levels

- D O U R - Respiration rate of biomass

- Sulphides

- Suspended solids

Case Study 3401 - Queenshead Gas Works, Queenshead, Handsworth

Contract- Chemiphase were approved by British Gas/Transco to treat all waste water and sludge from the Gasometer.

All waste water was to be treated to meet the Transco, Environment agency and the Severn Trent consent limits. The water was removed, treated using a Biosure Bioreactor system and discharged into the Severn Trent waterways. The sludges were removed, dried and sent to an approved landfill site according to local and national laws.

Due to the success of the Queenshead gas works project, British Gas/Transco approved Chemiphase for work on 6 further Gas Projects around the country.

Case Study 3402 - Teesdale Development Corporation,

Thornby Site Phase 1 and 2

Contract : to treat contaminated water on an 80 acre industrial sit, to remove high levels of contaminants such as heavy metals (Zn, Pb, Sn) organic compounds (benzene, toluene, xylene, PAH’s) phenolics, cyanide, ammonia.

Phase 1: Chemiphase designed and built a plant to treat 300 tonnes per hour of contaminated water.

All of the water, once processed was pumped into the river tees at the correct rate and to the discharge consent agreed with the environment agency, who sampled waters on a regular basis. Chemiphase supplied all of the plant, the technological expertise, the biological and chemical supplies and operators to run the plant at a rate of 300 tonnes per hour, 24 hours a day for 4 months.

Phase 2: Chemiphase was nominated for phase 2 due to the success of the phase one operation. This entailed a further 80 acre site and a plant to treat a further 500 tonnes per hour, on a 24 hour basis, for 25 weeks.

As part of our Biosure Bioreactor programme we undertake thorough sample taking and laboratory testing. This is in part to identify the areas that need to be addressed to meet national regulations and discharge consents but to also check the effectiveness of the Bioreactor at every stage.

As such Chemiphase have a huge amount of first hand data gathered directly from waste water treatment sites. This data allows us see which treatment plans were most effective, meaning that your waste water treatment package has the benefit of years of application and refinement.

Chemiphase Bioreactor Common Questions

For further information or to arrange a complimentary waste water lab test to see which Biosure package including the biological wastewater treatment system would be best suited to your needs please contact us directly on 08456 432 900 or email us at sales@chemiphase.co.uk

The information and all further technical advice is based on our present knowledge and experience. However, they imply no liability or other legal responsibility on our part, including with regards to existing third party intellectual property rights, especially patent rights. In particular, no warranty, whether express or implied of guarantee of product properties is intended or implied. We reserve the right to make any changes according to technological progress or further developments. The customer is not released from the obligation to conduct careful inspection and testing of incoming goods. Performance of the product described herein should be verified by testing, which should be carried out by qualified experts in the sole responsibility of the customer.